When designing a solar PV system it’s critical to know the minimum and maximum number of PV modules that can be connected in series, referred to as a string. PV modules produce more voltage in low temperatures and less voltage in high temperatures. If too many modules are on the same string then the maximum input voltage of the inverter may be exceeded and the electrical equipment connected to that string could be damaged, or worse, start a fire. If too few modules are on the same string, then the inverter might shutoff when the outside temperature is high and the system will underperform during the summer months.

Manual String Size Calculations

How to Calculate Minimum String Size

The minimum string size is the minimum number of PV modules, connected in series, required to keep the inverter running during hot summer months.

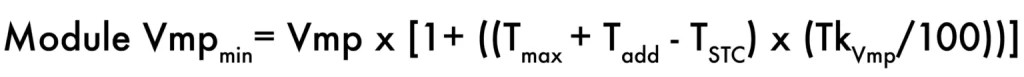

In order to calculate the minimum string size we first have to calculate the minimum output voltage, Module Vmp_min, that each module will produce for the specific installation site. Then take the inverter minimum voltage and divide by the calculated module minimum voltage to get the minimum number of modules.

The module minimum voltage is calculated using the high temperature for the installation site when the modules would produce the lowest expected voltage. This is because as a PV module gets hotter it is less efficient and produces less voltage.

Where:

Module Vmp_min = minimum module voltage expected at site high temperature [V].

Vmp = rated module max power voltage [V]. Found on the module data sheet.

Tmax = the ambient high temperature for the installation site [°C].

Tadd = temperature adjustment for installation method [°C].

The temperature is adjusted to take into account the installation method. In general, roof mounted systems get hotter than ground mounted systems because there is typically less airflow and the roof surface radiates heat.

- Roof mounted, parallel to roof (<6 in. standoff): +35°C

- Roof mounted, rack-type mount (>6 in. standoff): +30°C

- Ground or pole mounted: +25°C

T_STC = temperature at standard test conditions, 25°C

Tk_Vmp = module temperature coefficient of Vmp [%/°C], always expressed as a negative value. Found on the module datasheet.

This is not the same as the temperature coefficient for Voc. Most often the temperature coefficient of Vmp isn’t on the module datasheet. You can use the power temperature coefficient instead since this will be almost the same.

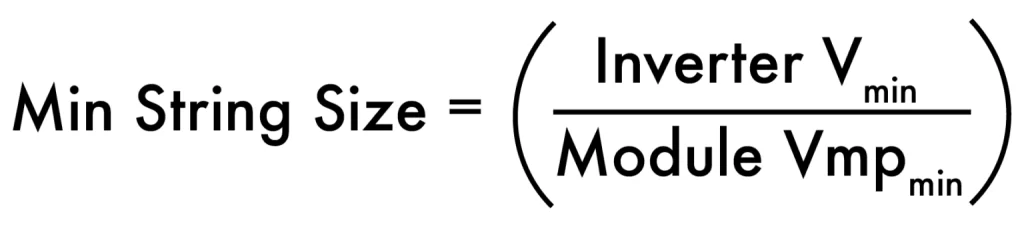

Where:

Module Vmp_min = minimum module voltage expected at site high temperature [V], from the previous calculation above.

Inverter Vmin = the inverter minimum MPPT voltage [V].

- Using the inverter minimum operating voltage will ensure that the inverter will keep running, however, the Max Power Point Tracking (MPPT) function of the inverter may stop working. This is the function that ensures the inverter is producing the maximum possible power output at any given time.

- Using the inverter minimum MPPT voltage will ensure that the inverter is running and the MPPT function is working properly, giving the highest possible performance.

The calculated minimum number of modules in a string must always be rounded up to the next whole number so that the minimum inverter voltage is being met.

Let’s assume we’re designing a PV system in Ludhiana, OR that is roof-mounted, parallel to the roof using Renewsys N Type Topcon 650 Wp modules and Havells string inverters ENVIRO GTi 20000TD

From the module datasheet

Vmp = 47.93 V

Tk_Vmp = -0.2764 %/°C

T_STC = 25°C

From the inverter datasheet

Inverter Vmin (MPPT) = 230 V

Tmax (2% ASHREA) = 33°C

Based on the mounting type, Tadd = 35°C

First, we will calculate Module Vmp_min:

Module Vmp_min = Vmp x [1+ ((Tmax + Tadd – TSTC) x (Tk_Vmp/100))]

= 47.93V x [1+ ((33°C + 35°C – 25°C) x (-0.2764%/°C / 100))]

= 47.93V x [1+ ((43°C) x (-0.2764/°C))]

= 47.93V x [1+ (-0.118852)]

=47.93V x [0.8815]

= 42.25 V

This calculation shows you that the minimum module voltage expected at this site’s high temperature is about 88% of the rated module Vmp.

Next, we will calculate the minimum string size:

Min String Size = Vmin_inverter / Module Vmp_min

= 230V/42.25V

= 5.44

Lastly, we will round up to the nearest whole number:

Min String Size = 6 modules

How to Calculate Maximum String Size

The maximum string size is the maximum number of PV modules that can be connected in series and maintain a maximum PV voltage below the maximum allowed input voltage of the inverter.

- Using the module open-circuit voltage temperature coefficient and the lowest expected ambient temperature to correct the PV module rated open-circuit voltage. (The method used in this article).

- For PV systems 100kWac or greater, using an industry-standard method provided by a licensed professional electrical engineer.

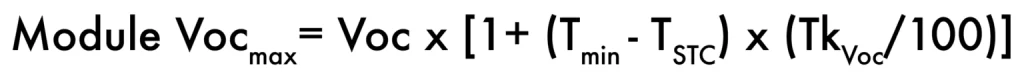

Using the first method , the Module Voc_max is calculated using the site lowest expected ambient temperature when the modules would produce the highest expected voltage.

Where:

Module Voc_max = maximum module voltage corrected for the site lowest expected ambient temperature [V].

Voc = module rated open current voltage [V]. Found on module data sheet.

Tmin = lowest expected ambient temperature for site [°C].

T_STC = temperature at standard test conditions, 25°C.

Tk_Voc = module open current voltage temperature coefficient [%/°C], always expressed as a negative value. Found on module data sheet.

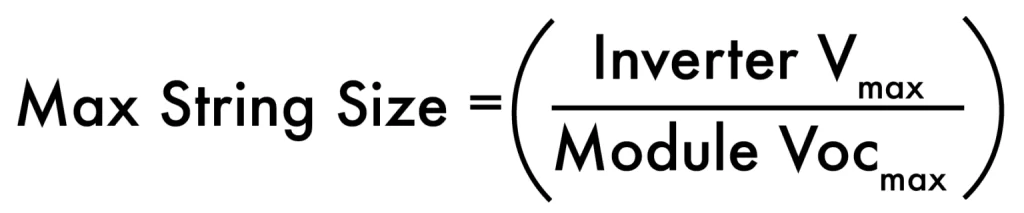

Where:

Module Voc_max = maximum module voltage corrected for the site lowest expected ambient temperature [V] from previous calculation above.

Inverter Vmax = the inverter maximum allowable voltage [V]. Found on inverter data sheet.

The calculated maximum number of modules in a string must always be rounded down to the next whole number so that the maximum inverter voltage is not exceeded.

Example

Let’s assume we’re designing a PV system in Corvallis, OR that is roof mounted, parallel to the roof (<6in. standoff) using Renewsys N Type Topcon 650 Wp modules and Havells string inverters ENVIRO GTi 20000TD.

From the module datasheet

Voc = 58.34 V

Tk_Voc = -0.2764 %/°C

T_STC = 25 °C

From the inverter datasheet

Inverter Vmax = 960 V

Based on the site location

Tmin = 0 °C

First, we will calculate the Module Voc_max:

Module Voc_max = Voc x [1 + (Tmin – TSTC) x (Tk_Voc/100)

= 58.34 V x [1 + (0°C – 25°C) x (-0.2764 %/°C /100)]

= 58.34 V x [1 + (-25°C) x (-0.2764/°C)]

= 58.34 V x [1 + (0.1122)]

= 58.34 V x [1.1122]

= 62.37 V

This calculation shows you that the maximum module voltage expected at this site low temperature is about 7% higher than the rated module Voc.

Next, we will calculate the maximum string size:

Max String Size = Inverter Vmax / Module Voc_max

= 960 V / 62.37 V

= 15.39

Lastly, we will round down to the nearest whole number:

Max String Size = 15 modules

Multiple Allowable String Sizes

For the example above, the allowable string size is between 6 to 15 modules. That means that we have the flexibility of choosing 6 to 15 modules connected in series on one string. Depending on the available installation space and system layout we might need to use a mix of string sizes. When using multiple string sizes we want to make sure that all the strings going into one MPPT have the same number of modules. Having multiple string sizes connected to the same MPPT is one cause of mismatch, the variation of input power from one string to another. Mismatch affects the MPPT’s ability to function properly and will result in decreased inverter performance.

Every inverter manufacturer has a team of applications engineers who can help you determine proper system design with their products. If you’re ever unsure of what string sizes to use with a particular inverter you can contact the technical support team for the inverter manufacturer.